What Is Automatic Film Processing In Radiography.

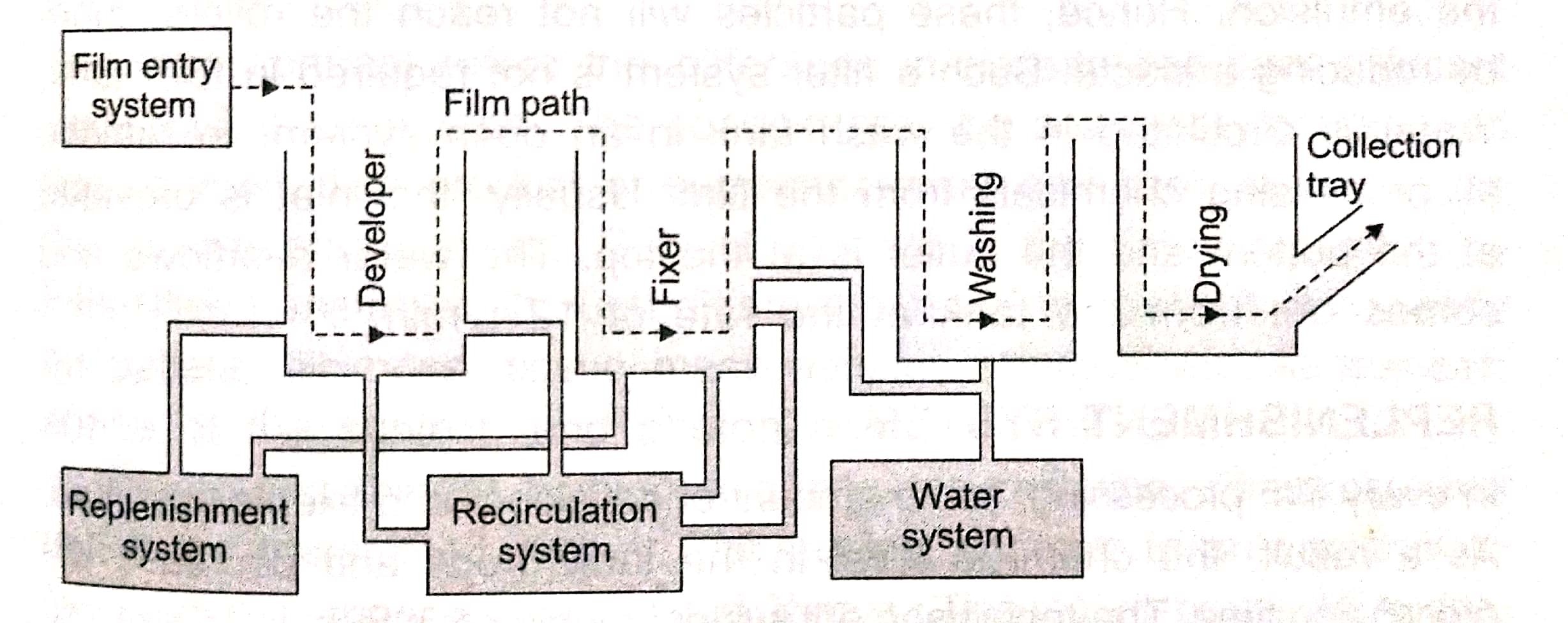

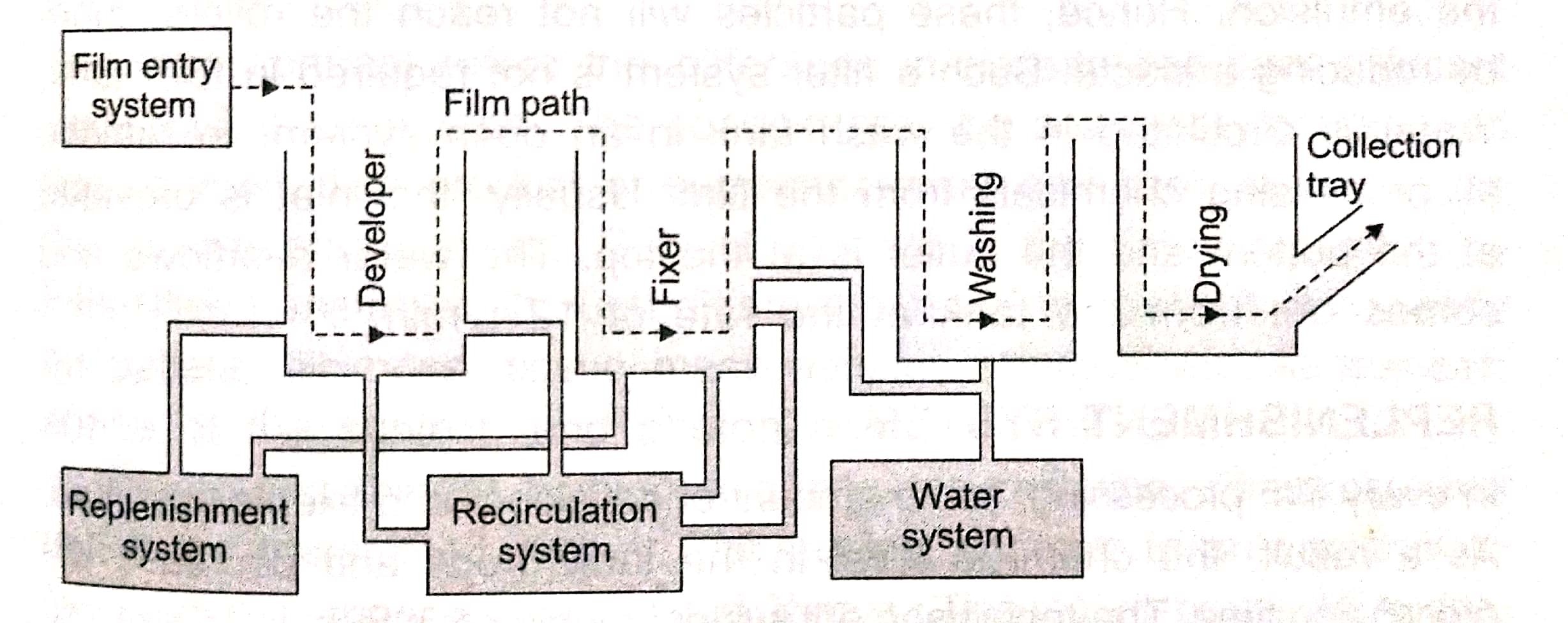

Today film processing is done by automatically. It is provided the best quality and minimum time. The automatic processing film run through the sequentially. The automatic processing contain the developer, fixer and washing solution. The total developing time is 90 sec.

The automatic film processing is done by following system.

A) Transport system.

B) Temperature control system.

C) circulation system.

D) Replenishment system.

E) Dryer system.

A) Transport system:- The transport system means it transport the film on the series. The transport system contains of tray, entrance rollers, micro switch , roller assembly, transport racks and drive motor. The roller assembly consist of transport rollers, master rollers and planetary roller. The film is kept into the feed tray in the darkroom. The transport rollers are in pairs. The transport rollers are composed of opposite side to one another and keep the film is correct path.The master rollers help the film to turn around with the help of planetary rollers and guide shoes. The transport rack help the film move one tank to other tank .A drive motor with 10-20 rpm transfer power to transport rack and drivers and rollers through belt and pulley or chain and sprocket or gears. The micro switch controls the replenishment rate of the processing chemicals.

B) Temperature control system:- The temperature of developer, fixer and washing maintenance precisely. The developer temperature is maintained at 95 degree F (35 degree C). Washing water temperature is maintained 5 degree F (2.8 degree C). The temperature control in each tank is provided by Thermostatically controlled heating element.

C) Circulation system:- The circulation system is pump the chemicals continuously and provides agitation in each tank. The developer and fixer chemicals should be mixed by agitation to the constant temperature. The circulation system is filter the particles which release from the emulsion in developer solution. So these particles are not reach the roller. Circulation of water through the wash tank is done with an open system fresh water top is piped into tank at the bottom and overflow out top, where it is collected and discharged directly to the sewer system.

D) Replenishment system:- The replenishment system monitor this loss and preserve both quality and quantity of the chemicals in the processor. In each and every film the some amount of developer and fixer chemical is absorbed. Thus, it decrease the the processing time. The replenishment consist of replenishment tank, filter and pump. It maintain alkalinity and strength in developing solution.

E) Dryer system:- in dryer system, it consist of blower, heater, ventilation duct, drying tubes and exhaust system. This system work on negative air pressure and absorbs moisture from the film. The blower sucks the room air and blows on the heating coils. The drying tubes are position on both sides of the film and the hot moist air is vanted out.

Fig:- Automatic Film Processing

rg64912@gmail.com